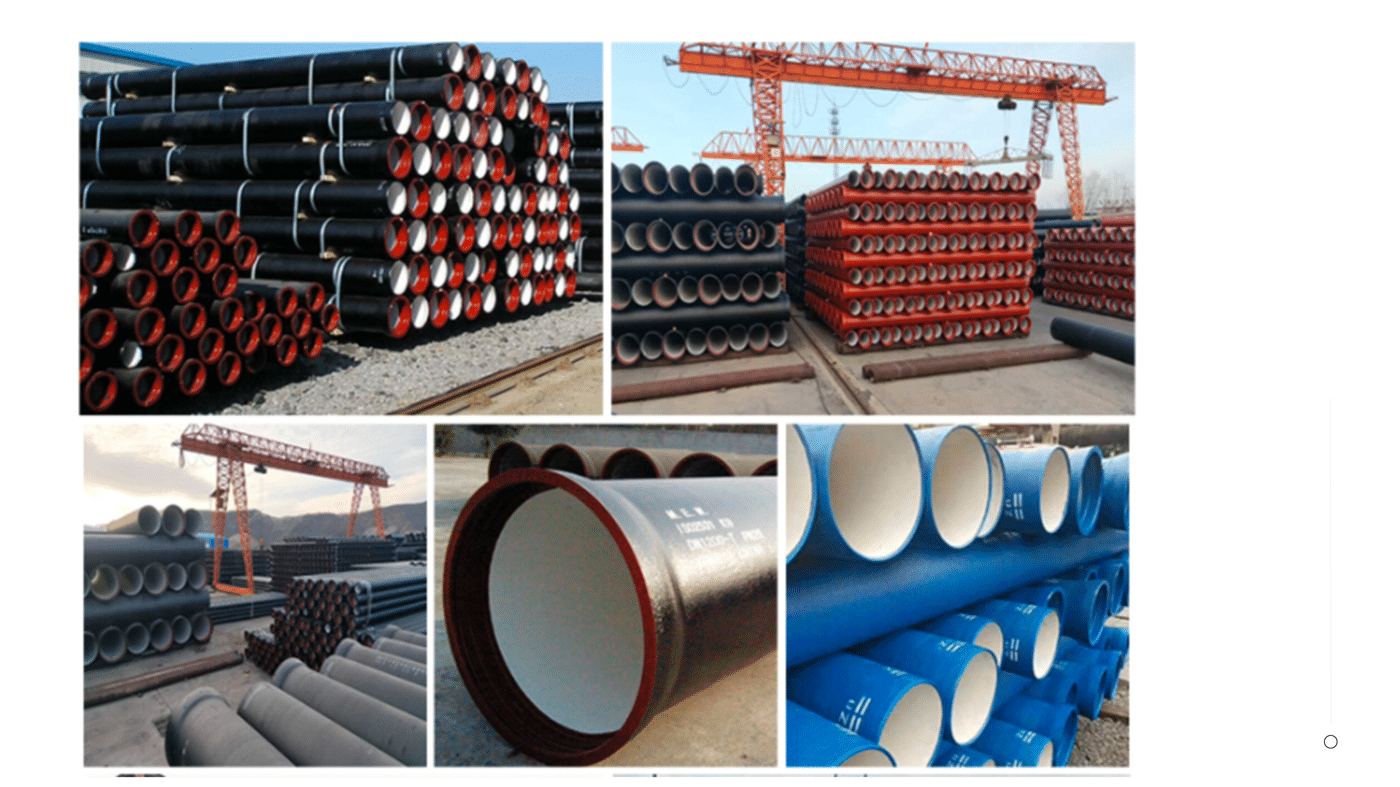

Kumukūʻai hale hana 2024 Kūʻai wela C25 Grade Ductile Iron Pipe K8 K9 900mm Ductile Iron Pipe Cement Lined Pipe

Huahana Huahana

Paipu kila hao nodulars he mau paipu hao ductile, nona ke ano o ka hao a me na waiwai o ke kila, nolaila ko lakou inoa. ʻO ka graphite i loko o nā paipu hao ductile aia ma ke ʻano spherical, me ka nui maʻamau o 6-7 mau māka. Ma keʻano o ka maikaʻi, pono e hoʻomaluʻia ka pae spheroidization o nā paipu hao hao ma nā pae 1-3, me ka nui o ka spheroidization o ≥ 80%. No laila, ua hoʻomaikaʻi ʻia nā ʻano mechanical o ka mea ponoʻī, nona ke ʻano o ka hao a me nā waiwai o ke kila. Ma hope o ka annealing, ʻo ka microstructure o nā paipu hao ductile he ferrite me kahi liʻiliʻi o ka pearlite, nona nā waiwai mechanical maikaʻi, no laila ua kapa ʻia ʻo ia hoʻolei.paipu kila hao.

| Hiki ke hoʻopilikino ʻia nā huahana kikoʻī āpau e like me nā koi o ka mea kūʻai aku | |

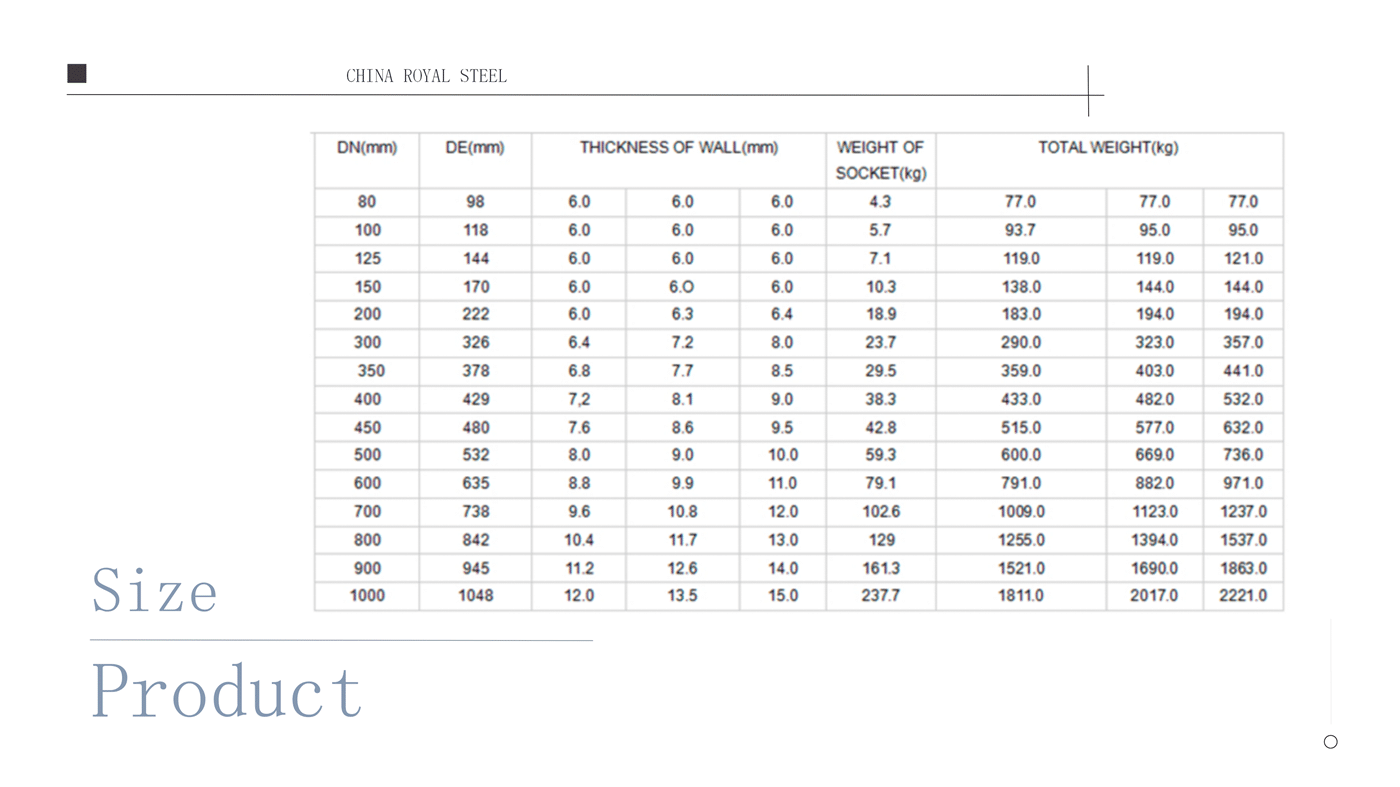

| 1. Nui | 1)DN80~2600mm |

| 2)5.7M/6M a i ʻole e like me ka makemake | |

| 2. Kūlana: | ISO2531, EN545, EN598, etc |

| 3.Material | ʻO ka hao hao GGG50 |

| 4. Kahi o kā mākou hale hana | Tianjin, Kina |

| 5. Hoʻohana: | 1)Wai kūlanakauhale |

| 2) nā paipu hoʻohuli | |

| 3) mahiʻai | |

| 6. Ka uhi loko: | a). ʻO ka lining mortar sima Portland b). ʻO ka paʻakai sima kūpaʻa kūpaʻa Sulphate c). Kiʻekiʻe-Alumikina kimeka paʻa d). ʻO ka uhi epoxy i hoʻopaʻa ʻia e). Pena epoxy wai f). Pena kiʻi bitumen ʻeleʻele |

| 7. Ka uhi waho: | . zinc+bitumen(70microns) pena . ʻO ka uhi epoxy i hoʻopaʻa ʻia c). Zinc-aluminum alloy+wai epoxy pena |

| 8. ʻAno: | Weled |

| 9. Hana Hana | Kuʻi, Kuʻi, Kuʻi, Decoiling, ʻoki |

| 10. MOQ | 1 tona |

| 11. Hāʻawi: | Nā pūʻolo, i ka nui, |

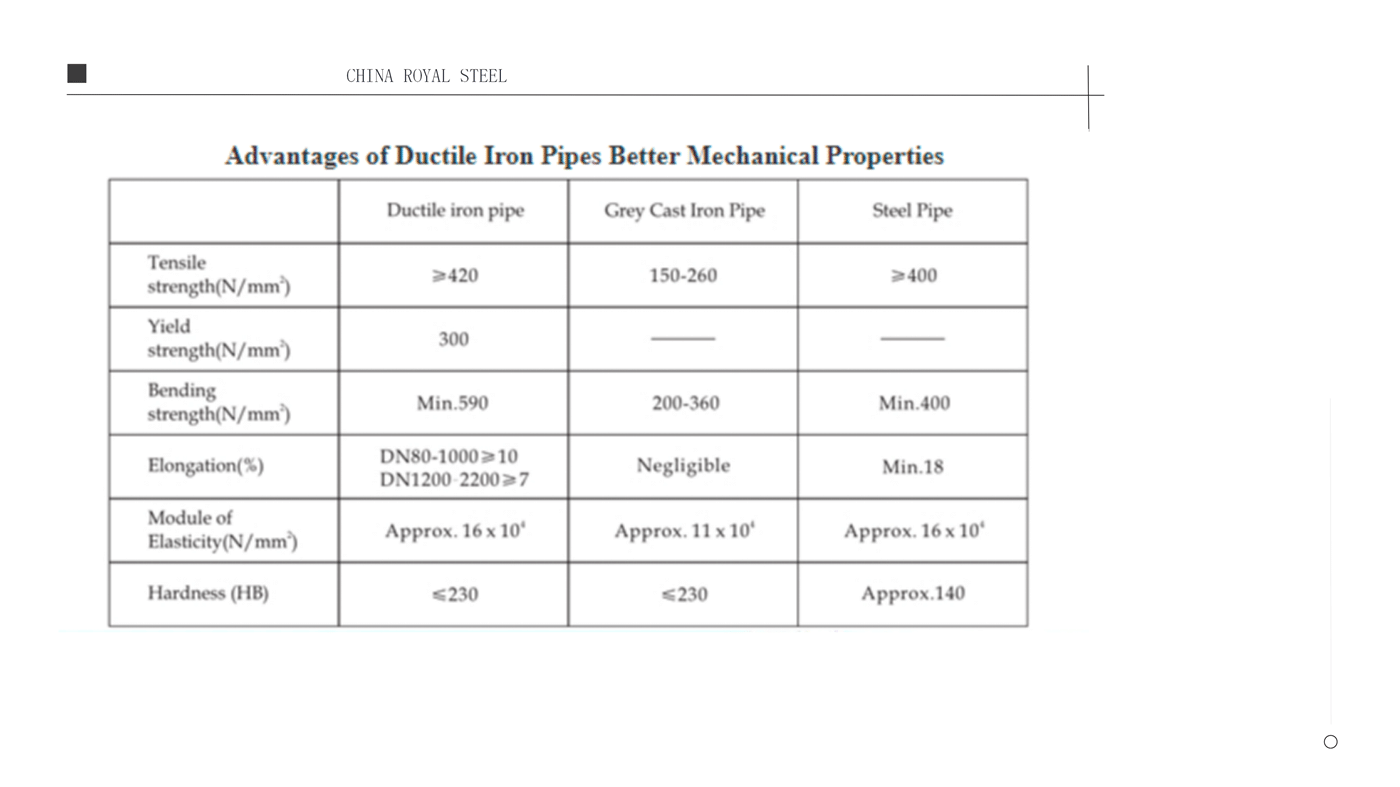

1. Ke kū'ē kū'ē i loko:ʻO ka paipu hao Ductile ka ikaika o ke kila me ka paʻakikī o ka haoʻo ia ka koho palekana. Hoʻohana ʻia ke kaomi hana kiʻekiʻe, a ʻoi aku ka nui o ke kaomi ʻana i ʻekolu manawa o ke kaomi hana.

2.External Pressure Resistance: ʻO ke kūpaʻa kiʻekiʻe o ke kaomi ʻana, ʻo ia ka mea e pono ai ka liʻiliʻi o nā moena kūikawā a i ʻole ka uhi ʻana, e ʻoi aku ka maʻalahi o kāu hoʻonohonoho ʻana.

3. Inner Anti-Corrosion Layer: Hoʻopili ʻia nā paipu me ka mīkini sima e like me ISO 4179 no nā noi wai inu. Hāʻawi kēia kaʻina hana i kahi lining maʻemaʻe a paʻakikī e pale ai i ka wai inu a ʻaʻole paheʻe a ʻōpala.

4.Paʻa Paʻa: Zinc spraying (≥130 g/m², ISO 8179) a me ka chlorinated Resin pena e hiki ai ke pale maikaʻi i ka ʻino. Hiki ke hāʻawi ʻia nā ʻāpana zinc mānoanoa a i ʻole ka zinc-aluminium coatings e like me nā kikoʻī o nā mea kūʻai aku.

Nā hiʻohiʻona

Paipu hao ductilehe ʻano paipu hao. Hana ʻia nā paipu hao ductile ma kahi pae 1-3 o ka spheroidization (Spheroidizationrate> 80%) e hoʻomaikaʻi i nā waiwai mechanical ma o ka hoʻohana ʻana i ka ikaika o ke kila a me ka paʻakikī o ka hao. ʻO ka paipu annealed he hale ferrite me kahi liʻiliʻi o ka pearlite, a he kūpaʻa maikaʻi ka corrosion, ductility, sealing performance a maʻalahi no ka hoʻokomo. ʻIke lākou i ka hoʻohana nui ʻana i ka lako wai, ka lawe ʻana i ke kinoea, a me ka lawe ʻana i ka aila ma ke kūlanakauhale a me ka ʻoihana.

Hoʻopuni ʻia ka graphite spherical e kahi matrix o ka ferrite a me ka pearlite. ʻO ka nui o ka pearlite i ka ferrite e pili ana i ka nui o ka paipu a me kāna mau elongation koi: no ka hapa nui, nā paipu liʻiliʻi liʻiliʻi he pearlite ≤20% a me nā paipu nui-diameter ≈25%.

Palapala noi

ʻO nā paipu hao ductile i ka nui mai 80 a 1600 mm pili i ka wai inu (BS EN 545) a me nā ʻōnaehana wai (BS EN 598). Hoʻohui maʻalahi lākou, hoʻokomo i kēlā me kēia manawa, maʻamau me ka ʻole o ka backfill kūikawā, a hāʻawi i kahi kumu kiʻekiʻe o ka palekana me ka hiki ke kū i ka neʻe ʻana o ka honua, e hoʻolako pono iā lākou no ka hoʻohana ʻana i nā noi pipeline.

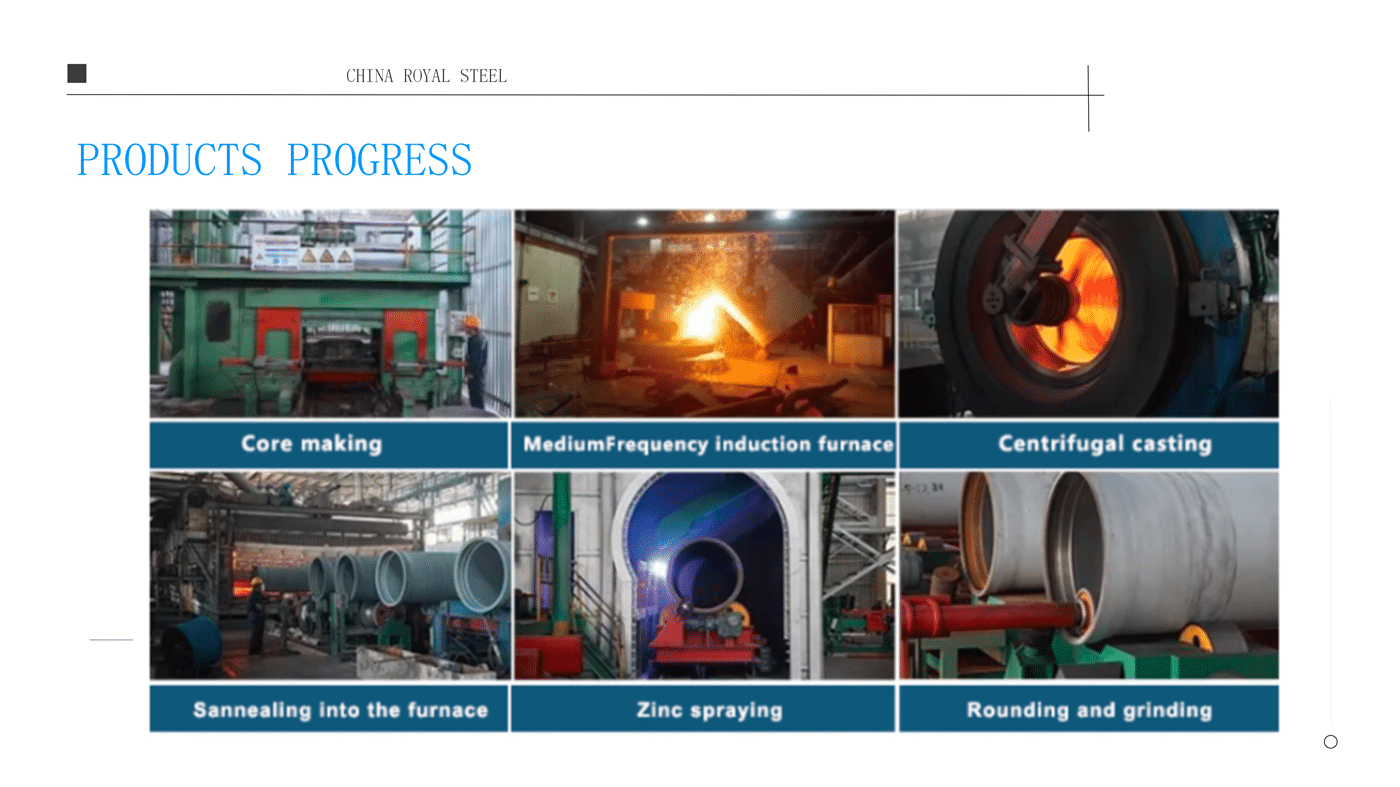

Kaʻina Hana Hana

Hoʻopili a me ka hoʻouna ʻana