Nā huahana

-

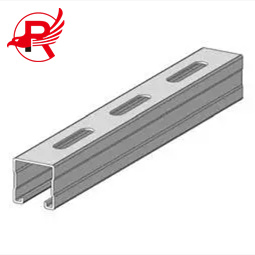

ʻO ke kahawai kila kila ʻano U no ka hapa nui o nā nui

Hoʻomaikaʻi i ke kūpaʻa a me ka palekana o nā panela photovoltaic: ʻO ka makani a me ke kaomi e loaʻa ana i nā panela photovoltaic e loaʻa iā lākou kahi hopena. No laila, i ke kau ʻana i nā panela photovoltaic, pono ʻoe e koho i kahi bracket kūpono a hoʻoponopono i ke kihi o ka bracket e hoʻomaikaʻi i ke kūpaʻa o nā panela photovoltaic. ʻO ke kūpaʻa a me ka palekana e hōʻoia ʻaʻole e hōʻino ʻia nā panela photovoltaic e nā mea kūwaho maikaʻi ʻole.

-

ʻO ke kahawai kila C Gavanized i hoʻoluʻu ʻia me ka wela, Strut Channel

E hoʻomaikaʻi i ka pono hoʻololi o nā panela photovoltaic: Hiki i nā brackets Photovoltaic ke hoʻokomo i nā panela photovoltaic ma nā kihi a me nā kuhikuhi kūpono e hoʻonui i ka omo ʻana o ka ikehu o ka lā a me ka hoʻololi ʻana i ka ikehu uila.

-

Mea Hoʻolako Gula Kumukūʻai Kūpono i Hoʻopilikino ʻia U-Shapped Carbon Steel Strut Channel

ʻO kahi bracket photovoltaic kahi hale i hoʻohana ʻia e kau i nā panela photovoltaic. ʻAʻole wale kāna hana e hoʻopaʻa i nā modula photovoltaic ma ka honua a i ʻole ka hale, akā e hoʻoponopono pū i ke kihi a me ke kuhikuhi ʻana o nā modula photovoltaic e hoʻonui i ka pono o ka omo ʻana o ka ikehu lā.

-

Pale Photovoltaic Pale Pale Haʻalulu 41*41*2

Hiki i nā pale Photovoltaic ke hoʻopaʻa paʻa i nā panela photovoltaic ma ka honua a i ʻole ka hale, a hiki ke pale pono i ka hopena o ka makani, ka ua, ka hau a me nā kūlana kūlohelohe ʻē aʻe mai nā ʻaoʻao like ʻole ma nā panela photovoltaic.

-

Nā Kaula Kūlana ʻEulopa HEA & HEB | Kila Kūkulu Ikaika S235 / S275 / S355 | Nā ʻIke Kūkulu Kaumaha

Nā kaola kila ʻEulopa ikaika kiʻekiʻe no ke kūkulu ʻana i nā mōlina, nā alahaka, nā ʻūpā kaumaha a me nā hale ʻoihana; ʻOi aku ka kaumaha a me ka mānoanoa o HEB o HEA akā ʻoi aku ka māmā ma mua o nā kaola HEM.

-

Nā Kaula Flange Laulā ASTM A992 | Kila Kūkulu Ikaika Kiʻekiʻe | Loaʻa nā Nui Kaula W āpau

ʻO nā kaola ASTM A992 W he mau kaola kila kūkulu me ka ikaika kiʻekiʻe no ka hoʻohana ʻana i ke kūkulu ʻana a me ke kūkulu ʻana i ke alahaka, loaʻa ka hiki ke hoʻopili maikaʻi ʻia, nā waiwai mechanical like a me ka hana wānana i nā mōlina kūkulu.

-

ʻO nā ʻōnaehana palekana piha o ka laka apo Porti Scaff Scaff

ʻO ke ʻano o ka scaffolding i hoʻohana ʻia i kēia lā, ʻo ia ka disc scaffolding i haku ʻia me nā uprights, crossbars a me nā diagonal bars, hiki ke hoʻākoakoa ʻia i loko o nā ʻōnaehana piha me ka hoʻohana ʻana i nā mea hoʻopili. ʻO ka hapa nui o nā paipu he galvanized wela-dip e pale ana i ka popo a me ka haki ʻana i ka mālama ʻana i ka wā lōʻihi. He kūpono ke kumukūʻai, maʻalahi ke hoʻākoakoa, wikiwiki a palekana. ʻAe ka disc scaffolding i ke komo kū pololei, ka hana ma luna, ke kau ʻana o nā ʻāpana kū pololei ma luna, a me nā pā palekana peripheral, akā naʻe, ʻaʻole kūpono ia no ka hoʻopili pololei ʻana i ka hana hoʻopau kūloko a ʻaʻole hoʻi i ka hana haʻahaʻa loa.

-

Ke kūʻai pololei aku nei ka mea hana ʻo Tianjin Scaffolding i ka hoʻokomo maʻalahi ʻana i ke kila Scaffolding Frame

ʻO ka scaffolding disc, nona nā kū pololei, nā kaola keʻa, a me nā kaola diagonal me nā mea pili ponoʻī, ua galvanized ʻia me ka wela, maʻalahi e ʻākoakoa, palekana a kaulana no ke komo ʻana i luna, ka hoʻopili ʻana ma luna a me nā kahua hana no ka hoʻohana manawa pōkole.

-

ʻO ke kūkulu ʻana o ka Scaffold Scaffolding Oem Q235 Steel Powder Coated Door Type Masonry Frame Scaffold

Hoʻohana nui ʻia ka scaffolding disc ma ka mākeke o kēia manawa. Hana ʻia ia me nā kū pololei a me nā kaola keʻa me nā kaola diagonal ke hoʻohana ʻia me nā mea hoʻopili scaffolding, lilo lākou i mau hale piha. ʻO ka hapa nui o nā paipu scaffolding he galvanized hot-dip, ʻo ia ka uhi e pale ai i ka metala mai ka ʻōpala a me ka hōʻino i ka hala ʻana o ka manawa. He waiwai kēia mea hana, maʻalahi e lawelawe, wikiwiki a palekana hoʻi e hoʻohana. Hiki i nā scaffolding i nā limahana ke hele i luna a i lalo a hana ma nā paia periphery, e kau i nā hana duct overhead a me nā hana ʻē aʻe i luna, ʻoiai ʻaʻole pono e hoʻohana ʻia no ka hana hoʻopau pololei i loko o ka hale a i ʻole ma nā wahi me nā ʻokoʻa kaupaku haʻahaʻa loa.

-

ʻO ka ikaika kiʻekiʻe o ka Alloy haʻahaʻa ASTM A572 Papa 50 Steel I-Beams Nā nui kūikawā i loaʻa Structural Steel I-Beam

ʻO nā kaola I-kila ASTM A572 Papa 50 he mau kaola kūkulu haʻahaʻa-alloy ikaika kiʻekiʻe e hāʻawi ana i ka hiki ke lawe ukana maikaʻi loa a me ka hiki ke hoʻopili ʻia no nā hale, nā alahaka, a me nā hale ʻoihana. -

Nā ʻIkepili Kūkulu Kila ʻAmelika ASTM A572 I beam

ʻO ke kila ASTM I-beam kahi ʻano kila kūkulu nona kahi pūnaewele kū pololei ma kona waena e hoʻopili ana i ʻelua mau mokulele ākea ma kēlā ʻaoʻao kēia ʻaoʻao. Loaʻa iā ia ka lakio ikaika i ke kaumaha maikaʻi loa, ka hiki ke hāpai i nā ukana maikaʻi a maʻalahi hoʻi e hana, ma muli o ia mea he nui nā noi i ke kūkulu hale ʻana, nā alahaka a me nā ʻoihana.

-

Kumukūʻai Kūpono o ka Hale Hana Pre-Galvanized Slotted C Channel Steel 41 × 41 / 41 × 21 Strut Channel Systems

Kahawai C i hoʻopaʻa ʻiahe kila C channel me nā lua i hoʻomaka mua ʻia a hiki ke hoʻohana ʻia i nā ʻano hana like ʻole me ke kākoʻo no nā pipelines, nā kaula, a me nā lako e hiki ai ke hoʻouka wikiwiki a me ka maʻalahi o ka hoʻonohonoho ʻana.